Technology Manufacturing & Robotics: Third-Party Logistics and Warehousing

Tighe Logistics offers tailored solutions that meet the exacting requirements and high level of service that technology manufacturing sector demands.

Our expertise in supplier management and just-in-time delivery to manufacturing helps technology manufacturing companies achieve their goals.

Logistics & Warehousing for Technology Manufacturers

Ready for a better logistics and warehousing solution? Get in touch with a Tighe expert today.

Tighe Logistics: Tech Manufacturing Services and Solutions

Tighe provides customers with the highest quality, full service, completely integrated warehousing and transportation solutions available. Tighe Logistics has the people and expertise to manage your suppliers, be your warehouse distribution hub, your factory annex, or an extension of your manufacturing floor. Here are some of the services we offer:

Supplier Management

We can receive, store, and ship inbound raw materials, sub-components and parts from suppliers that are used in manufacturing processes. From inbound receiving, to developing item masters and uploading into the WMS, to developing uniform shipping requirements for suppliers that streamline processes and reduce costs, and more.

Precise, Transparent Inventory Management

At Tighe, we understand that our operational performance means a production line never shuts down in our client’s manufacturing facilities. Our experienced team specializes in managing thousands of manufacturing parts from suppliers with precision and accuracy your business requires — from the tiniest washer to a pallet-sized robot arm. We can meet your fill rates, provide on-time delivery, and optimize replenishment processes for JIT manufacturing.

JIT Manufacturing Expertise

We’re experts in JIT manufacturing warehousing and transportation to help ensure an efficient, cost-effective supply chain.

JIT relies on the efficient coordination of raw materials, components, and finished goods to minimize inventory and reduce waste. We can manage the transportation, warehousing, and distribution of goods, ensuring that components and finished products arrive at the right place, at the right time, and in the right quantity.

Full Service Transportation and Transportation Management

We offer an in-house transportation fleet that covers the entire Northeastern United States. As an extension of your team, our logistics crew will assist you with supply chain planning, day-to-day execution and strategic partnerships that will reduce your freight costs and improve operational efficiencies. We fully support transportation solutions for JIT manufacturing and more.

Some of our specialties include:

LTL/TL

We offer flexible shipping options for both LTL and Truckload shipping. We help customers choose the right option depending on factors such as shipment size, urgency, and cost considerations.

Cross Dock/Pool Distribution

A quick, cost effective way to move product efficiently through the supply chain. With our ability to cross dock your products from inbound railcars, Tighe can help streamline your supply chain from point of origin to point of destination and reduce your costs.

Drayage Services

With our experienced fleet of TWIC certified drivers, we are able to provide extensive port and intermodal drayage service to all rail yards and piers in the Northeast. In addition, Tighe provides transloading, consolidation, deconsolidation, and warehousing services for overseas shipments.

Dedicated Fleet Services

Tighe’s dedicated fleet services and highly-trained drivers provide the benefits of a private fleet without the associated liabilities and capital investment, allowing customers to concentrate on running and growing their businesses. Tighe can provide a dedicated fleet operation of any size.

Value-Add Services

Tighe offers a variety of value-added services ideal for technology manufacturing companies — and that complement our core transportation and New England warehousing services.

-

Pick & Pack

-

Sub-Assembly

-

Labeling/Packaging/Repackaging

-

UPC Barcode Printing

-

Overflow/Seasonal Warehousing

-

Kitting

Technology

The Latest Technology To Support Your Business

With state-of-the-art hardware, software and business applications, including our WMS, Tighe is able to provide highly accurate, real-time information that can be used to integrate seamlessly with your supply chain management or ERP systems.

Integrated TMS and WMS Systems

Real-Time Tracking and Reporting

Automated Order Processing

Advanced Inventory Management Software

Data Analytics and Insights

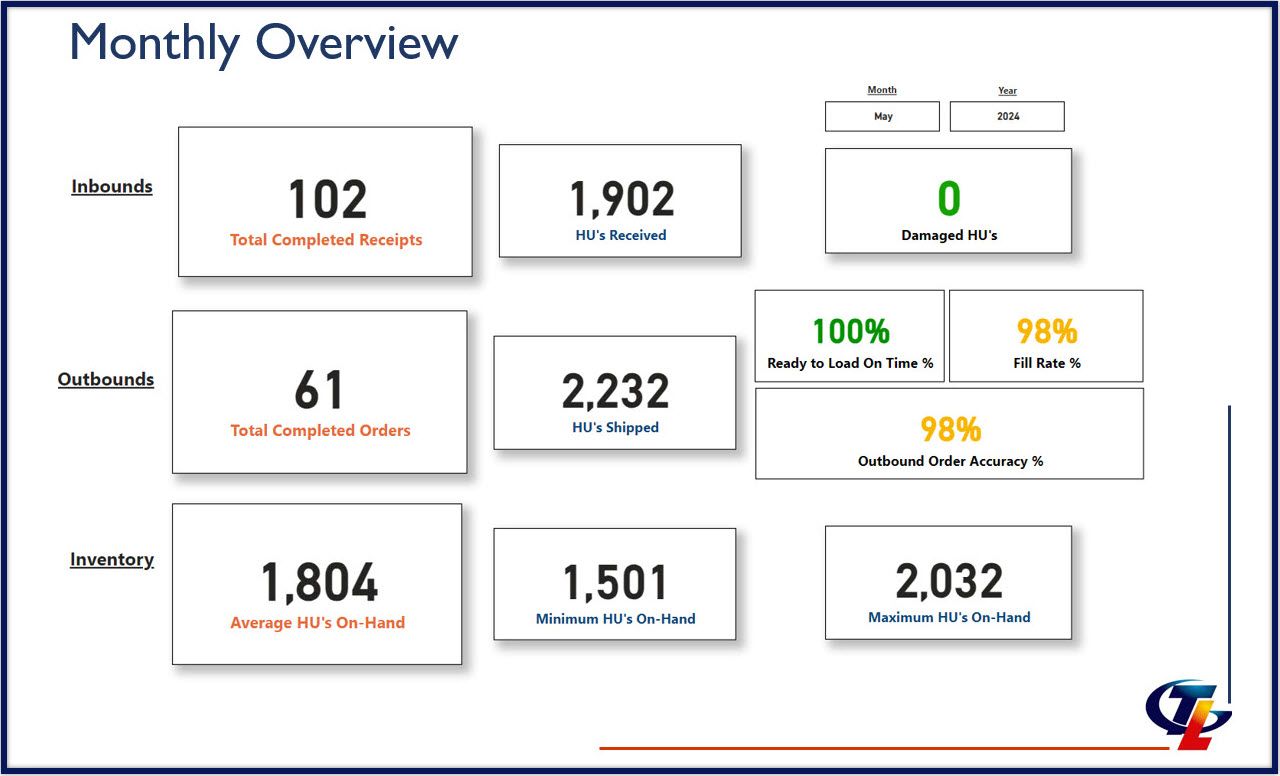

Real-Time Visibility Into The Metrics That Matter

Tighe provides on-line access for customers, giving them visibility to all aspects of their business. In addition, customers have their own dashboard with key metrics, so they can always be up-to-date.

Reverse Logistics

Tighe can handle returns, including replacing products, returning them to inventory, or disposing of them properly.

Compliance Reporting

Tighe helps you meet your safety and compliance requirements as well as provides the supporting data and reports you need.

Why Tighe Logistics: Ideally Located in Boston,

the Silicon Valley of the East

the Silicon Valley of the East

Boston and its surrounding areas, including Cambridge and the Route 128 Tech Corridor, are home to a significant number of tech companies. There are hundreds of tech companies in and around Boston. These include established companies as well as startups and research institutions, covering a wide range of industries such as biotechnology, software development, robotics, and telecommunications. Many major tech companies have a significant presence in the Boston area including Google, Amazon, Microsoft, and IBM, among many others.

Eastern Massachusetts is home to a skilled workforce familiar with the technology sector. A 3PL located in this area can tap into this talent pool, ensuring that they have the expertise needed to provide high-quality logistics services to tech companies. The tech corridor is well-connected with highways, airports, and other transportation infrastructure. This ensures that the 3PL can easily move goods in and out of the area, providing efficient logistics solutions to tech companies.

Tighe offers multiple warehouse locations in the Boston metropolitan area, including:

Winchester

Woburn

We have additional locations in:

Avon

Clinton

Mansfield

Being at the epicenter of the tech corridor means Tighe can offer efficient and cost-effective logistics solutions. We have a deep understanding of the unique logistics challenges including handling delicate and high-value equipment, managing just-in-time inventory requirements, and dealing with rapid changes in demand.

Key Metrics And Performance You Can Expect From Tighe Logistics

Tighe can provide the metrics and KPIs that help you make better decisions faster. Our teams are dedicated to providing you with the information you need — here are a few of the ways Tighe helps tech manufacturing customers stay ahead of business trends:

Access to Customized Dashboards

Tighe’s customized daily dashboard keeps you up-to-date on important metrics and provides complete transparency.

Conducting Monthly Business Reviews

To review key metrics, make adjustments and smarter business decisions about what’s happening with inventory, distribution and the supply chain.

Tracking Productivity by Job Function

We can track work-specific productivity by job function, enabling you to identify specific functional areas for improvement gains.

Identifying Opportunities for Improvement –

By looking at different job groups, we can break down processes in a granular way and find what types of products or processes are driving costs.

Implementing Best Practices

Our team has the data analytics and process expertise to ensure your warehousing and transportation is operating optimally at every stage.

Proven Track Record In Technology Manufacturing

Cost Reduction Strategies for a Global Electronics Supplier

Focus: Cost Reduction

With volatile and uncertain economic conditions and demand slowing post-pandemic, our client’s parent company mandated a 30-40% cost reduction across the board in all operations. Leveraging Tighe Logistics’ operational data and industry expertise, we helped them meet their cost reduction goals.

-

45% Labor Cost Reduction

-

49% Transportation Cost Reduction

-

25% Warehouse Storage Cost Reduction

Is Your Supply Chain Running Smoothly?