Food & Beverage Industry: Third-Party Logistics and Warehousing

Tighe Logistics is a full-service 3PL that provides tailored warehousing and logistics solutions to help food companies like yours better serve your customers and control costs.

Logistics & Warehousing for the Food Industry

Ready for a better logistics and warehousing solution? Get in touch with a Tighe expert today.

About Us

Tighe Logistics: A Wide Range of Food Industry Services and Solutions

Tighe provides customers with a full service, high-quality, completely integrated warehousing and transportation solution. Tighe Logistics has the people and expertise to manage your suppliers, be your warehouse distribution hub, deliver products to your end customers, and more.

Whatever you need, from production to packaging and storage, to distribution to retailers, restaurants, and convenience stores – we can help every step of the way. Here are some of the services we offer:

Precise, Transparent Inventory Management

Our experienced team specializes in managing all types of food products with the precision and accuracy your business requires — from bulk goods that fuel your manufacturing lines to finished goods ready for the shelf. We can meet your fill rates, provide on-time delivery for manufacturing, meet delivery windows and stringent specifications for grocery chains, as well as optimize replenishment processes. End-to-end service capabilities include receiving, cross-docking, sorting, re-stacking, order management and outbound delivery.

JIT Manufacturing Expertise

We’re experts in JIT manufacturing, warehousing and transportation to help ensure an efficient, cost-effective food supply chain.

JIT relies on the efficient coordination of raw materials to keep food production lines running at capacity. We can manage the transportation, warehousing, and distribution of goods, ensuring that raw materials arrive at food production locations without interruption. We also deliver finished products to the right place, at the right time, and in the right quantity.

With thorough and efficient supplier management, we help customers reduce lead times, lower inventory holding costs, and improve overall supply chain efficiency. We offer value-added services including, picking, packing, kitting, packaging, labeling, quality control to meet your specific needs.

Full Service Transportation and Transportation Management

We offer an in-house transportation fleet to serve all New England markets. As an extension of your team, our logistics experts and experienced drivers will assist you with supply chain planning and day-to-day execution that will reduce your freight costs and improve operational efficiencies. We support all types of transportation in the food supply chain, from JIT delivery to manufacturing facilities to final-mile delivery to retail grocery chains, convenience stores, restaurants, and more. Some of our specialties include:

LTL/TL

We offer flexible shipping options for both LTL and Truckload shipping. We help customers choose the right option depending on factors such as shipment size, delivery site requirements, and cost considerations.

Cross Dock/Pool Distribution

A quick, cost effective way to move product efficiently through the supply chain. With our ability to cross dock your products from inbound railcars, Tighe can help streamline your supply chain from point of origin to point of destination and reduce your costs.

Railcar Services

With facilities serviced by major rail lines including CSX, Norfolk Southern and Pan AM, Tighe offers our customers the ability to ship inventory via railcar into or out of our facilities.

Drayage Services

With our experienced fleet of TWIC certified drivers, we are able to provide extensive port and intermodal drayage service to all rail yards and piers in the Northeast. In addition, Tighe provides transloading, consolidation, deconsolidation, and warehousing services for overseas shipments.

Dedicated Fleet Services

Tighe’s dedicated fleet services and highly-trained drivers provide the benefits of a private fleet without the associated liabilities and capital investment, allowing customers to concentrate on running and growing their businesses. Tighe can provide a dedicated fleet operation of any size.

Last mile delivery

Value-Add Services

Tighe offers a variety of value-added services ideal for food companies — and that complement our core transportation and New England warehousing services.

Pick/Pack

Our pick/pack services ensure efficient and accurate selection and packaging of products, streamlining the fulfillment process and reducing errors.

Kitting

We offer kitting solutions that assemble multiple items into ready-to-ship kits, enhancing product organization and improving delivery speed.

Order Assembly and Fulfillment

Our comprehensive order assembly and fulfillment services guarantee timely and precise preparation and dispatch of customer orders, enhancing overall satisfaction.

Promotional Packaging, Such as Store Aisle End Caps

We specialize in promotional packaging, such as end caps, to create visually appealing displays that boost product visibility and drive sales.

Labeling / Packaging / Repackaging

Our labeling, packaging, and repackaging services ensure that products are presented professionally and meet all regulatory and branding requirements.

UPC Barcode Printing

We provide UPC barcode printing services that facilitate inventory management and streamline the checkout process, improving operational efficiency.

Overflow/Seasonal Warehousing

Our overflow and seasonal warehousing solutions offer flexible storage options to accommodate fluctuating inventory levels during peak periods.

Price Ticketing

Our price ticketing services ensure that all products are accurately tagged with current pricing, enhancing retail readiness and customer convenience.

Reverse Logistics

Tighe can handle returns, including replacing products, returning them to inventory, or disposing of them properly.

The Latest Technology to Support Your Business

With state-of-the-art hardware, software and business applications, including our WMS, Tighe is able to provide highly accurate, real-time information that can be used to integrate seamlessly with your supply chain management or ERP systems.

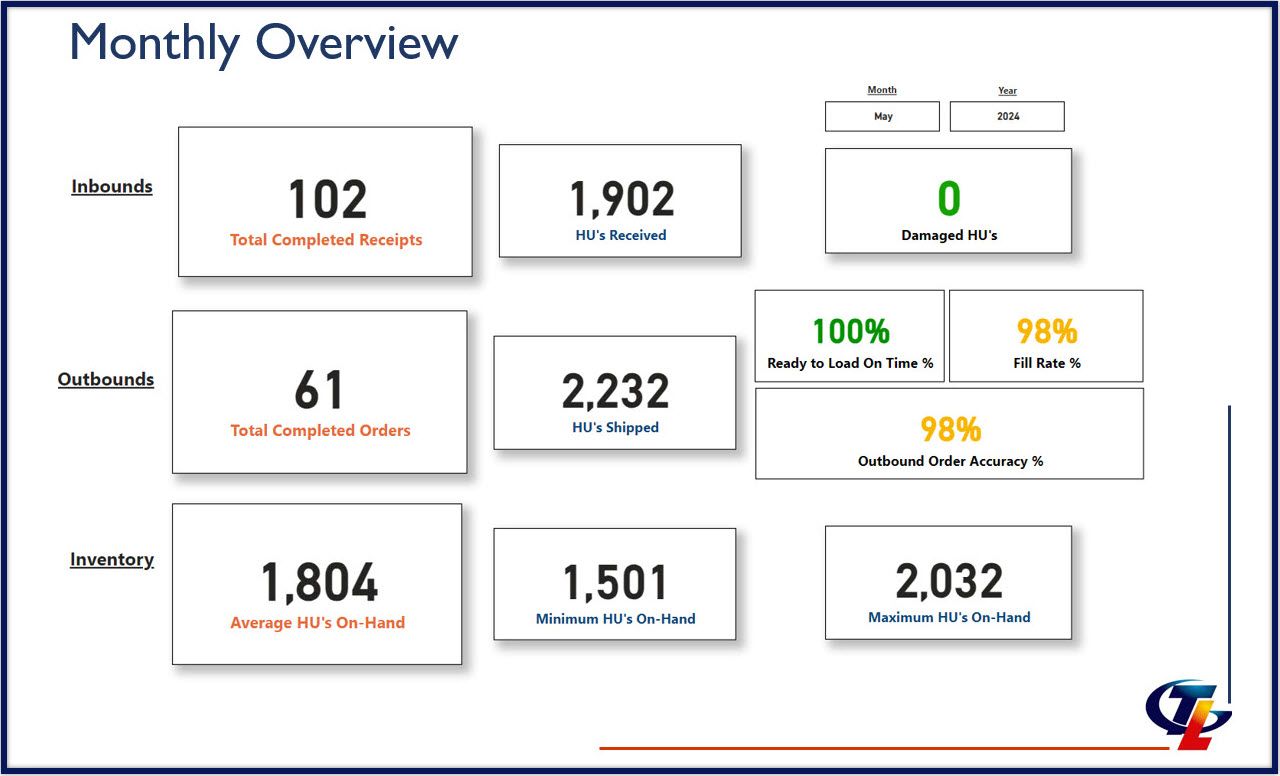

Real-Time Visibility into the Metrics that Matter.

Tighe provides on-line access for customers, giving them visibility to all aspects of their business. In addition, customers can access dashboards with key metrics, so they can always be up-to-date.

Dedicated to Food Safety and Compliance

Ensuring food safety and compliance is paramount in the warehousing and logistics sector of the food industry. At Tighe, we uphold the highest standards to protect the integrity, safety, and quality of the products we handle. Our comprehensive approach encompasses several critical aspects of food safety and compliance:

Food Safety and Sanitation

We prioritize rigorous food safety and sanitation protocols. Our facilities undergo annual Current Good Manufacturing Practices (CGMP) audits to meet and exceed industry standards. These audits ensure that we maintain required pest control measures, sanitation practices, and meticulous documentation. This commitment to hygiene and safety is foundational to our operations, preventing contamination and ensuring the highest quality of stored and transported goods.

Site Defense Against Food Fraud

At Tighe, we implement robust site defense strategies to eliminate any risk of food fraud. We ensure that ingredients are not misrepresented as whole, organic, or any other falsely attributed quality. This vigilance helps maintain the authenticity and trustworthiness of the products we handle, safeguarding consumer trust and brand reputation.

Allergen Segregation

We recognize the critical importance of allergen segregation in our facilities. By meticulously separating allergens such as wheat, soy, dairy, sesame, and nuts, we prevent cross-contamination and protect consumers with allergies. This rigorous approach to allergen management is an essential component of our food safety strategy.

Certifications and Audits

Tighe’s dedication to food safety is validated by our prestigious certifications. We are FDA registered and certified by AIB, and we consistently excel in CGMP food safety audits. These certifications are a testament to our unwavering commitment to maintaining and enhancing our food safety standards.

Food Accuracy and Lot Control

Maintaining food accuracy is essential for consumer trust and regulatory compliance. We implement strict lot control measures, ensuring traceability and monitoring expirations. Our lot segregation practices meet stringent requirements, preventing the shipment of mixed lots to customers. This meticulous attention to detail ensures that our clients receive products that meet their exact specifications and quality standards.

Tighe stands out for our comprehensive and proactive approach to food safety and compliance. Our unwavering commitment to these principles not only ensures the safety and quality of the food products we handle but also strengthens the integrity and efficiency of the entire supply chain.

Ideally Located in Boston. Serving all of New England

Massachusetts and the Northeast are home to a skilled workforce. Tighe can tap into a deep talent pool, ensuring that we have the expertise needed to provide high-quality logistics services. Well-connected with highways, airports, and other transportation infrastructure, Tighe can easily move goods in and out of the area, providing efficient logistics solutions to our building materials industry customers.

Tighe offers multiple warehouse locations in the Boston metropolitan area, including locations in Winchester and Woburn, with additional warehouses in Avon, Clinton, and Mansfield MA.

Key Metrics And Performance You Can Expect From Tighe Logistics

Tighe can provide the metrics and KPIs that help you make better decisions faster. Our teams are dedicated to providing you with the information you need — here are a few of the ways Tighe helps food industry customers stay ahead of business trends:

Access to Customized Dashboards

Tighe’s customized daily dashboard keeps you up-to-date on important metrics and provides complete transparency.

Conducting Monthly Business Reviews

To review key metrics, make adjustments and smarter business decisions about what’s happening with inventory, distribution and the supply chain.

Tracking Productivity by Job Function

We can track work-specific productivity by job function, enabling you to identify specific functional areas for improvement gains.

Identifying Opportunities for Improvement

By looking at different job groups, we can break down processes in a granular way and find what types of products or processes are driving costs.

Implementing Best Practices

Our team has the data analytics and process expertise to ensure your warehousing and transportation is operating optimally at every stage.

Find Out How Tighe Logistics Can Support Your Building Materials Industry 3PL Needs

Supporting Growth for a Local Family Farm Food Supplier

Focus: Customer Service at Delivery

This food supplier sources high-quality produce from local family farms all across the US. They had been using two different 3PLs to service their New England market, but weren’t getting the service they needed. They decided to consolidate their New England logistics needs with Tighe because of our reputation for taking care of ‘our customer’s customer’ especially at the point of delivery.

-

Smooth transition from a previous provider

-

Care & Attention given by Tighe drivers at the point of delivery

-

Robust KPIs that govern food-grade warehousing operation

Optimizing Logistics for a Premium Tomato and Olive Oil Producer

Focus: Long-term 3PL Partnership

This well-established premium food supplier prides themselves on producing the highest quality canned tomatoes and olive oil for use in restaurants across the country. As a high-end premium supplier, they sought a 3PL partner who could match the caliber and quality of their products. For the last 30 years, they have found that partner in Tighe Logistics.

-

260 Rail Cars unloaded per year

-

18,000 pallets managed per year

-

Orders are picked and delivered to local restaurants across New England.

Is Your Supply Chain Running Smoothly?